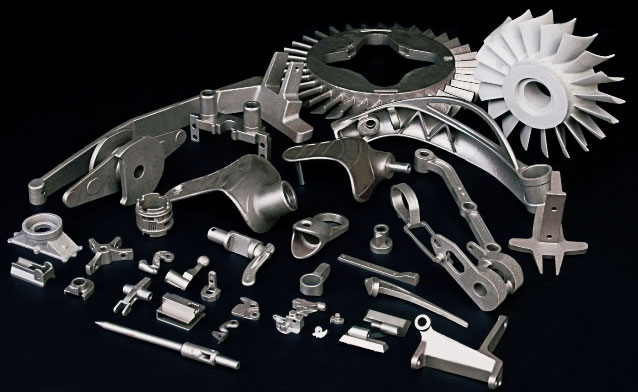

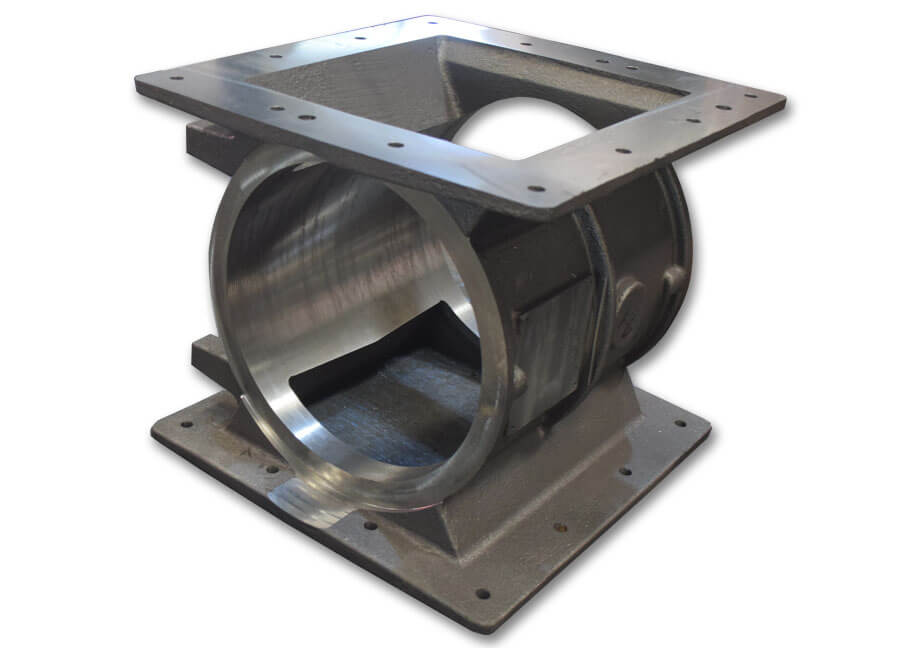

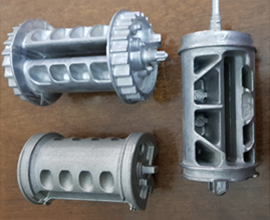

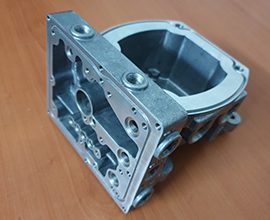

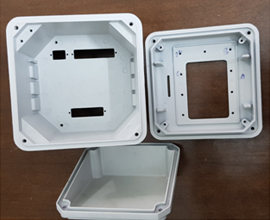

Investment Casting

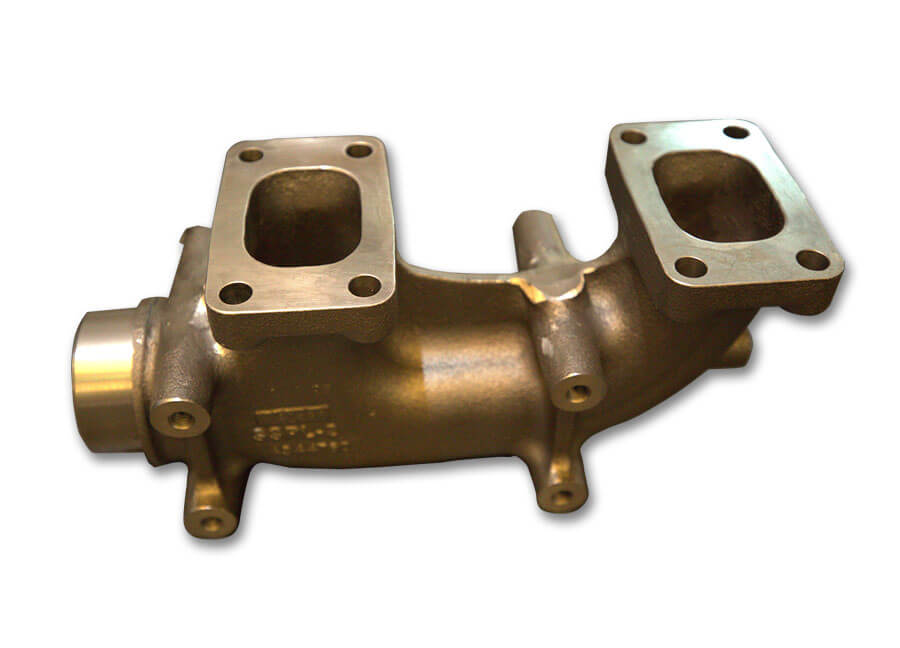

Materials

- Carbon Steel

- Low Alloy Steel

- High Alloy Steel

- Duplex Steel

- Copper Alloys

- Aluminium Alloys

- Vacuum Alloys

Integriti partners with a trusted network of Indian suppliers. Through a rigorous onboarding process and close collaboration from product development to final output, we ensure quality, capability, and transparency at every stage. To simplify business operations, we provide quotations in the currency of your choice.

We oversee the complete product lifecycle ensuring quality throughout. By consolidating shipments and managing logistics, we help you navigate current global challenges with confidence. Acting as an extension of your team in India, we eliminate the need for you to allocate local resources.

All our suppliers hold industry certifications like ISO, IATF, and undergo formal quality audits, and follow lean practices with Six Sigma expertise. Our supplier development engineers work closely on the shop floor to ensure excellence in design, tooling, and final product quality

Integriti’s warehousing facility in Bangalore consolidates shipments for destination-country warehouses, ensuring efficient inventory management and on-time deliveries. We also maintain agreed safety stocks to manage demand fluctuations, guaranteeing consistent product availability

Materials

Materials

The Integriti management team brings over two decades of experience in international business, highlighting our profound understanding of delivering exceptional value to our customers. We have dedicated local sales managers and support teams who represent us in various regions. From order processing to inventory management, and from fostering strong customer relationships to engaging with suppliers, we handle every aspect of the process. Our core strengths lie in effective risk mitigation, preserving value, enhancing supplier performance, and minimizing supplier management costs.

288/1 Lakshmipura, Thataguni Post, Kanakapura Main Road, Bangalore, 560082

bhavani(at)integritiglobal(dot)com